Stone Slab Lifting Equipment to Boost Productivity

Stone slab lifting equipment tools and devices are used to lift, transport, and handle heavy stone slabs and other raw materials. They are designed to overcome the need to manually lift and place these materials. These devices are critical in construction, masonry, and stone fabrication because they ensure worker safety, due to reduced heavy lifting and promote operational efficiency as installation is essentially automated and performed in a reduced length of time. Applications for these tools vary depending on the specific needs of a project, the type of stone being handled, and the safety requirements of the worksite.

The Unspoken Risks

While a large stone countertop might not seem significant to many stone professionals, it carries substantial weight and often has various size irregularities that can make transportation more challenging. During installation, slabs often need to be raised above cabinet height, which strains the installer further as they are required to balance the entire weight on one side of their body while leaning over to place it – an accident waiting to happen. Though these are all factors that exist at the point of installation, multiple points of the process require manual loading: loading onto the vehicle, lifting from the vehicle, loading onto the installation cart, and then, only after all of this will your team lift it into place for the installation. This continuous strain throughout each process has a significant negative impact on workers’ long-term health and safety.

To aggravate the situation more, primary installers seldom, if ever, get a break. The individuals on this team can’t afford to take time off for recovery, causing ignored minor injuries to escalate into chronic and severe conditions that prematurely end their careers. This makes it imperative that employers invest in equipment for their installers in the same way that they have invested in forklifts, booms, clamps, cranes, and vacuum lifters for their workshop team. It is about more than improving efficiency, it’s about preserving the health and well-being of your workforce. Our equipment has been designed to fill this gap.

The EZ Loader Difference

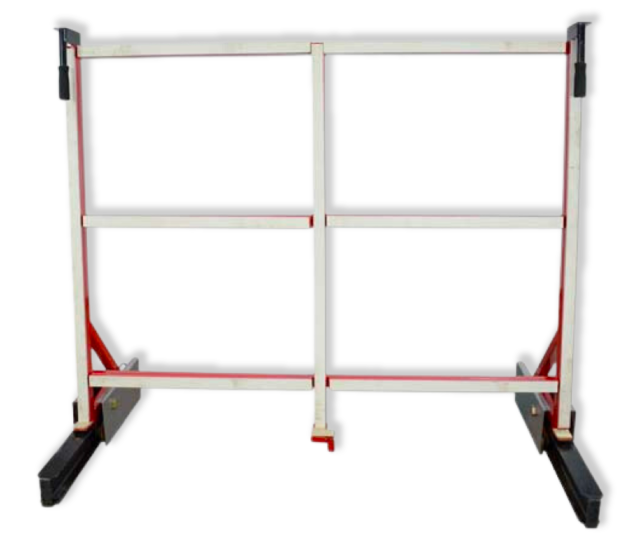

The EZ Loader is a game-changer for natural stone fabricators and installers. This piece of equipment, designed for easy use alongside the EZ Installation cart, solves several practical shop and installation risks and issues, making installations safer and easier. It is designed to reduce the injuries common with loading, unloading, and installing large pieces of stone and other heavy materials by eliminating physical stone lifting and has a loading capacity of 5000 pounds.

One of the biggest advantages of the EZ Loader is that it is no longer necessary to disrupt production by pulling the strongest team members from the shop to help the installation team get an Island off the truck or trailer and onto a countertop. A typical installation team consists of two to three installers, and large islands could require five to six people, depending on island size and site conditions. Using countertop fabricators from the shop to install large islands is not ideal for owners since that affects production, schedules and cost. With the EZ Loader, this inconvenience is eliminated.

Make Stone Lifting Easier with the EZ Loader

The Importance of Stone Slab Lifting Equipment

SAFETY

Stone slabs are heavy and can be the cause of severe injuries through traditional manual lifting, placement or the mishandling of the slab. Using our specialized lifting equipment helps reduce the risk of accidents, as it’s designed to lift, transport, and handle these heavy slabs safely without the requirement for any human intervention to assist with the physical demand of lifting, placement, etc.

EFFICIENCY

Our equipment makes handling slabs safer and more efficient. They allow workers to move and position stone slabs quickly and precisely, significantly speeding up work processes whilst lessening the required manpower. As the EZ Loader requires no heavy lifting during installation, it also presents scope to reduce the extent of manual labor present within the fabrication team. It simply rolls the island from the A-frame on the truck onto the EZ Installation Cart.

PRODUCT PROTECTION

Handling stone slabs is not only about safety and efficiency. Mishandling can lead to breakage, chipping, cracking, or other damage to the stone slabs or cabinets. Fabricators can now prevent or minimize such product damage and associated costs by using our specially designed equipment.

Reduce Injuries with the

EZ Loader

Investing in quality stone slab lifting equipment is crucial for the success of any modern stone-handling operation. By prioritizing the well-being and efficiency of your workforce, you are also investing in the longevity and success of your business. The EZ Loader’s benefits are undeniably compelling, making it an indispensable asset for any business dealing with stone slabs. Equip your team with the right tools and equipment and watch your operations thrive!

Frequently Asked Questions

Are there any safety considerations I need to know when using stone handling, transfer, and lifting equipment?

Yes, safety should always be a priority when using stone lifting and handling equipment. This includes ensuring that all operators are trained, that the equipment is used as instructed, and that all safety features function correctly. It is also important to regularly inspect and maintain the equipment to prevent malfunctions.

How cost-effective is investing in stone lifting and handling equipment?

While there is an upfront cost, this equipment will significantly increase productivity, reduce labor costs, minimize product damage, and decrease the risk of workplace injuries. Over time, these savings can more than offset the initial investment.

Can stone slab lifting equipment handle all sizes and weights of stone slabs?

Stone slab lifting equipment comes in various designs and capacities to handle different sizes and weights of stone slabs. Our EZ Loader has a maximum capacity of 5000 pounds, four times more than any countertops weigh. This allows it to be used to handle and transfer slabs up to 5 inches in thickness.

Invest in a safer, more productive tomorrow.