Innovative Stone Fabrication Equipment

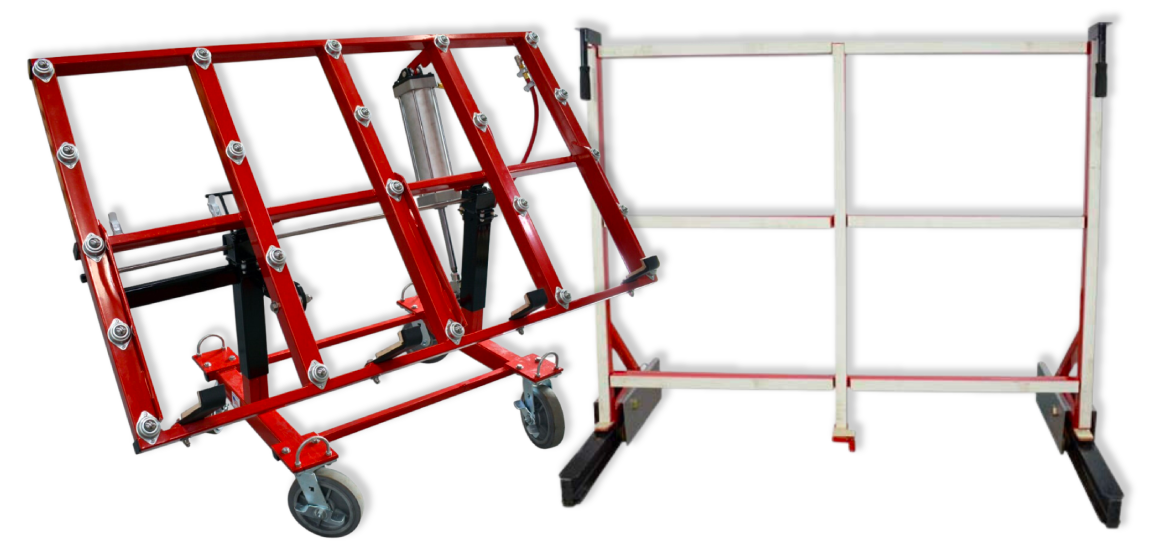

The EZ Installation Cart with the EZ Loader is a combination system designed by Louwrens Mulder. Mulder has been in the countertop fabrication and installation industry since 1990. Large islands weighing up to 1000 pounds and more have been inconvenient for installers for the longest time. Mulder has designed this system to improve and simplify the stone installation process. With these innovations, fabricators and installers can now reduce the risk of injury and improve project efficiency.

Stone Installation and Moving

Lifting natural stone during product installation is a meticulous and complex process. Natural stone, such as granite, marble, or quartz, are incredibly heavy, delicate and require high precision, care, and specialized equipment for professional installation. Since a single slab can weigh as much as 1000 pounds, lifting manually without risk of injury or damage to the stone is virtually impossible. For this reason, modern installation teams use various mechanical aids to safely maneuver these slabs into place. Despite these tools, there is often still a need for physical support to position it onto its landing – leaving room for injury. Our stone lifting innovations have successfully removed this risk without the use of any electricity, batteries or hydraulics.

It’s in The Name!

The beauty of the EZ Installation Cart and EZ Loader lies not only in their ability to enhance safety and efficiency but also in their user-friendly design! These units were specifically engineered with simplicity, making them EZ to operate. This means installers do not require extensive training to use them effectively. The EZ Loader, for instance, automates the loading process, reducing the need for manual handling. Similarly, the EZ Installation Cart has features like an air cylinder requiring only atmospheric air to safely lower large islands with a control valve. The EZ Installation cart is also equipped with locking wheels and brakes to ensure stability during installation.

Both pieces of equipment are designed to seamlessly integrate into the existing workflow, helping streamline fabrication and installation. Thus, while they bring revolutionary changes to the industry, they do not necessitate a steep learning curve, making the transition for use smooth.

Invest in a safer, more productive tomorrow.